Composite presses

Hydraulic composite press systems

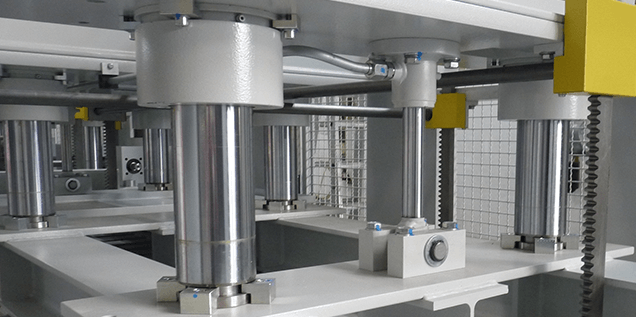

Joos manufactures hydraulic presses for pressing composite materials. High-tech materials are manufactured from fiber reinforced composite materials with carbon fibers or glass fibers. Innovative materials are shaped into high-quality products. Components can be produced for airplane manufacturing, the automotive industry and mechanical engineering. These materials stand out for their low weight and high stability. Composite pressing technology is designed for processing thermoplastics and thermosetting plastics and bonding them with fibers. Joos presses can process all commonly used materials such as CFRP (carbon fiber reinforced plastics), GFP (glass fiber reinforced plastics), BMC, SMC, and GMT.

Our innovative composite presses work using a heating and cooling system that can be connected to the in-house heating systems. This saves energy and costs. In addition, Joos presses are a space-saving option that can be effortlessly integrated into your production line.

Benefit from our expertise in system engineering for lightweight and structural components.

Overview of key points

- Up to 33,000 kN

- Press surface up to 6 m x 2.5 m

- Heating and cooling plates up to 450°C

- Aluminum or steel heating plates

- Process data recording and proprietary software

- Multi-daylight design possible

- Very durable and low-maintenance

- Simple operation

- Peripheral equipment like feeding systems available

- Data management and connection to Industry 4.0

- Custom presses according to customer specifications

Innovative partner for lightweight components and composite materials in production.

Composite technology and hydraulic systems for molding high-tech components.

Our service

Customer service on site

Our extensive dealer network guarantees fast customer service directly on site. Production problems can be solved quickly.

Telephone support

Of course, we are happy to assist you via telephone. You can contact our experts for your press directly. We are available via e-mail outside of our business hours.

Composite technology – press molding

Today, molded parts made of steel or aluminum are being replaced by fiber composite components in production. These parts offer higher strength at a lower weight, an important reason for the shift. In addition, composite materials are weather-resistant, corrosion-resistant, heat-resistant, and comparatively simple to process. Parts with decorative surfaces can also be pressed, for example for fittings, in addition to non-decorative components for internal installation.

Joos manufactures custom-tailored composite presses for producing lightweight components and structural components, such as those used in airplane construction. We are the experts in systems for molding thermoplastic materials and thermosetting plastics. We cover all components for composite press construction: switch cabinet, frame, controller, press-bear, hydraulic cylinder, press table, pressure distribution, and everything else needed for a high-quality, well-designed product. We support you from the start with all services from a single source. Whether you are looking for alternatives and want to convert your production to composite technology, or whether you have problems in your ongoing manufacturing, please get in touch with us!

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.