Veneer presses

Veneer presses for 80 years

We have been designing and producing veneer presses for over 80 years. Maintaining a leading position on the wood processing equipment market for decades demands production at the highest level of quality and a passion to precisely address customer needs. Veneer presses from Joos set new standards for expertise.

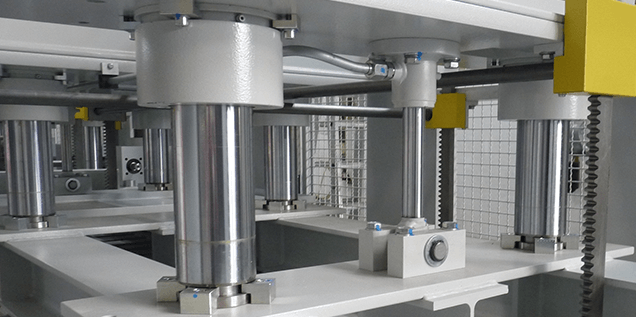

Expertise in quality: Our veneer presses have won multiple awards and are manufactured in-house with a high level of vertical integration. The press frame, the heart of the press, offers a high level of stiffness. The table design distributes the pressing force evenly to the panels, veneer, and glue. This produces high-quality veneered panels.

Expertise in safety: One external and one internal rip cord bring the press to a standstill in case of an emergency. Joos machines are equipped with our A.B.S. safety system. If materials are not picked up or set incorrectly, this is registered by sensors and the press opens automatically. This improves operational safety and the service life of the press, preventing damage to the press table. Side plastic guides serve as a safety breaking point. Other safety devices protect the operator.

In addition, as a manufacturer we place a high premium on ensuring convenient operation of our presses. That is why we deliver our veneer presses with variable swivel key operation. The optional SP controller can be operated via a touch panel.

Overview of key points

- Dynamic piston mounting

- Pressure and temperature are adjusted to the material and the glue

- Aluminum heating plates with a max. working temperature of 130°C

- Heating plates also available in steel

- Heating systems: Water, thermal oil or electric

- Working temperature up to 200°C possible as an option

- Protective film for heating plates

- Integration into in-house heating systems

- Other options: Disconnectible cylinder, removable storage for push-through operation

Custom sizes available for different pressing surfaces.

Veneer presses for wooden panels, doors, furnishings, and windows.

Our veneer press series

HP series

Joos quality HP presses – the classic choice

Veneer finishing with our classic machine. Our HP model is a reliable choice for manufacturing high-quality panels because we know what is most important. Optimal process technology is essential for good pressing results. Pressure and temperature must be applied and distributed across the panel evenly and tailored to the glue.

Another advantage are the dimensions of the hydraulic system. Because the hydraulic system is oversized, the hydraulic oil is protected against overheating, preventing premature aging.

BEU series

Joos quality BEU presses – variable application

Our BEU series is highly flexible, both in its design and applications: The adjustable limit switch, for instance, can be used to vary the press space opening. The heating plates can be heated with water, thermal oil or electrically depending on customer specifications.

The BEU series offers everything you need: Dynamic piston mounting, hard anodized heating plates, a powerful hydraulic unit and a safety system are included.

Our service

Customer service on site

We offer reliable customer service on site thanks to our extensive network of contracting partners. This guarantees quick repair of your veneer press by a professional technician.

Telephone support

Our experts are also happy to assist you by phone. If you experience problems outside of our business hours, simply write us an e-mail.

High-quality veneers

Joos veneer presses have been on the market for around 80 years, proving their quality right from the start. Many of our classic machines have been providing reliable service for over 60 years, and we continue to repair and maintain them as needed. This is proof of how robust and durable our veneer presses are. Of course, this also impacts their price at resale. Joos presses are highly sought-after on the used machinery market. A long service life ensures economic efficiency, sustainability, and a good environmental footprint.

Joos achieves this level of quality through a high range of vertical integration for its press systems. Almost all components are manufactured in-house. Primer and coatings are used to prevent rust on steel elements. The dimensions of the hydraulic system protect oil against premature aging. Robust and stiff press frames are optimized for specific applications.

Veneer presses from Joos are used to manufacture high-quality, decorative fronts for the furnishings industry using chipboard, multi-layer panels or composite panels.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.