Hydraulic presses

Hydraulic presses from the experts

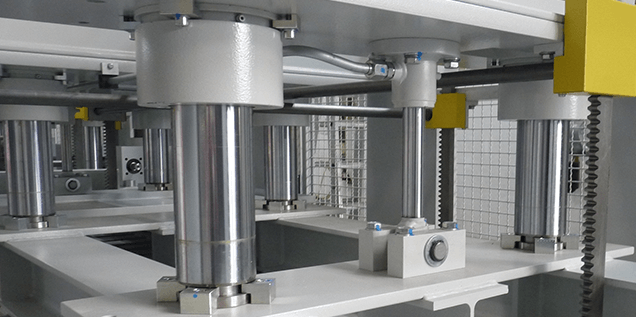

Hydraulic presses are a wide-ranging category. Their design and function are based on their application. All of these presses are built on the principle of transferring pressure to the workpiece via a hydraulic cylinder. The advantages of hydraulic presses are their ability to evenly distribute pressure over the entire piston stroke, and their comparatively simple construction. Designs range from two- or four-column presses to hydraulic C or H-frame presses. Presses from Joos can be adjusted to specific applications with different pressures, temperatures, and sizes.

Overview of key points

- Hydraulic presses with up to 33,000 kN pressing force

- Press surface area up to 18 x 3 m

- Press weight up to 80 t

- Heating medium: Water or thermal oil up to 450 °C

- Aluminum or steel heating plates

- Parameter selection: Pressure, temperature, time, position, and dimensions

- High-quality, low-maintenance hydraulic system

- Software and visualization from Joos

- Perfectly tailored presses for every application

- Available as daylight presses

- Excellent vertical integration of manufacturing – made in Germany

Flexible design depending on profile of requirements.

Joos builds durable, high-quality hydraulic presses.

Our hydraulic press series

HP series

Joos quality HP presses – the classic choice

Connecting the press to the existing heating system in production lowers energy and operating costs. This allows waste heat produced elsewhere in production to be used directly. All HP presses can be designed for this kind of connection.

In addition, high-quality heating and insulation elements ensure even pressure and heat distribution, guaranteeing high-quality products and improving the energy footprint of the press.

BEU series

Joos quality BEU presses – flexible application

Don’t make sacrifices. Each of the four models is equipped with all the advantages you expect from Joos: The BEU is designed to meet a broad range of requirements with dynamic piston mounting, a durable hydraulic unit, the Joos A.B.S. safety system, anodized heating plates and a flexible pressing space opening.

LAP series

Joos quality LAP presses – hydraulic presses in a laboratory format

For quality controlling or prototyping, basic research or product development. Laboratory presses can be used in a wide range of applications. Many universities, institutions and company laboratories use hydraulic presses in laboratory formats from Joos.

The versatility of our state-of-the-art presses ensures they can be used in many different fields.

DLP series

Joos quality DLP presses – through-feed presses

DLP – our solution for series production!

Economical, safe operation is ensured through state-of-the-art heating technology and specialized control technology. Thanks to the use of standardized components, Joos delivers a high-quality, safe and easy-to-operate hydraulic press with a long service life.

Our service

Customer service on site

We are always happy to assist you from our location for any needs you may have after your purchase. We handle customer service and repairs for you on site.

Telephone support

Our team is also available to support you by phone if you have any questions or experience faults. Give us a call or send us an e-mail, and we will handle your inquiry promptly.

Application and function of hydraulic presses

In general, the principle behind hydraulic presses is that ideal fluids are non-compressible. The pressure is transferred to the pistons via the fluid. This makes it possible to construct presses with a high level of pressing force and compact dimensions. Most workshop presses are hydraulic presses. Small hydraulic presses (arbor presses, bearing presses, frame presses) are primarily used in workshops.

Larger presses are used in different industries such as the wood processing, automotive, aviation and aerospace and packaging industries. Modern hydraulic units are able to build up high levels of pressure, and can be constructed for different tasks depending on their design. Hydraulic presses are used as punches, forming presses, veneer presses, etc. in production, and often in series manufacturing. Each press is optimized to its specific application. Joos has been manufacturing hydraulic presses for 80 years. Many of our presses have been in use for over 60 years. Our mission is to deliver exactly the presses our customers need. We know what is most important: high-performing, low-maintenance hydraulic units and cylinders, pumps, and frames with the right dimensions.

We want to be your partner from start to finish, not only with our solid mechanical engineering, but also with press controllers and peripheral equipment.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.