High-frequency presses

Presses for high-performance production

In applications with high quantities, high-frequency presses stand out for their short pressing times. Production is accelerated greatly by high-frequency glue application. HF presses are also necessary if parts exceed a certain thickness. If parts over 30 mm thick need to be pressed, the components cannot be heated through by commonly used heating systems. Heating such parts would take too long. A heating time of one minute is assumed for each millimeter of material thickness in common molded parts, in addition to the base time which varies by glue. During pressing, the glued joint is heated from both sides. This means that, for instance, if you wanted to press a product that was 12 mm thick, you would assume a pressing time of six minutes per workpiece, in addition to the base time. Above a certain material thickness, the times can become unfeasible. In addition, heating times depending on component thickness are not linear. Instead, the heating time curve flattens out.

Systems using a high-frequency generator are the solution. The glue is brought up to the required high temperature quickly. The pressed or molded part only needs to be under pressure for a short time (compensation time) for moisture to be removed from the part. With wooden molded parts, the time must be adjusted so that the wood retains its desired shape and is not affected by shocks due to steam. Otherwise, the workpiece could tear.

Take advantage of our experience in press engineering, and jump-start your high-performing production with us!

Overview of key points

- Increase performance in production

- Systems are designed to meet customer specifications

- Especially well suited for thicker molded parts (with low thermal conductivity)

- High-frequency, selective joint heating

- Glue cures quickly

- Joint is cured directly after pressing

- Effective and safe shielding of the high-frequency generator

- Connection of two presses per high-frequency generator, to use the generator effectively

High-performance machines for large quantities.

For safe technical operation of systems with high-frequency generators.

Our service

Customer service on site

We offer customer-focused service through our extensive customer service network. We always provide quick contact in case of faults and on-site service.

Telephone support

We are happy to support our customers by phone. If you do experience a problem outside of business hours, you can simply contact us by e-mail.

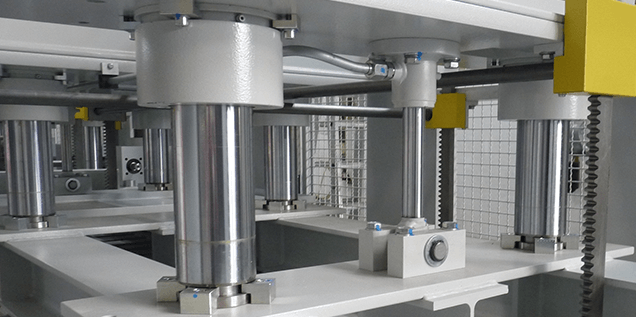

High-frequency presses from Joos

High-frequency presses from Joos are in operation in many different industries. They are used to manufacture a wide range of products, such as panels, fins, molded parts for the packaging industry or the construction sector. They can be operated as multi-daylight presses. We recommend systems in which one high-frequency generator is installed for two presses, to fully utilize the generator’s capacity. While the parts are heated up and pressed in one press, the other press can be emptied and fed. This ensures efficient use of the generator.

As a press specialist, we are glad to adapt our high-frequency presses to customer requirements. Please get in touch with us!

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.