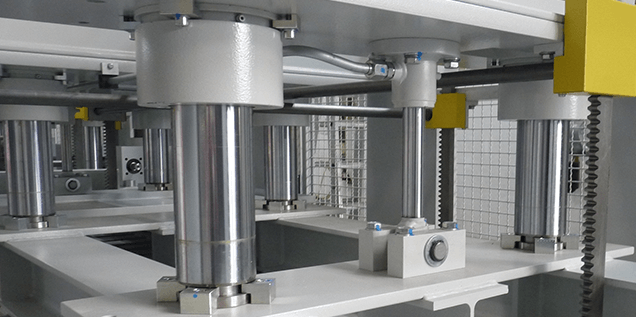

Hot presses

Heated presses – Hot presses

Hot presses from Joos are pressed that can be heated. In this type of press, the heat is transferred to a workpiece. The heat is used to shape the products or to bond a variety of materials and components to a product. The temperature, pressure, cycle time, heating system, and size of the pressing space can be tailored to customer requirements, depending on the application.

The technology offers excellent surface quality and strength for component manufacturing. Changing colors or materials is simple. Our successful HP, BEU, LAP and DLP presses can also be operated as hot presses.

Overview of key points

- Pressing force up to 33,000 kN

- Press surface area up to 18 x 3 m

- Heating / cooling plates up to 450 °C (different systems)

- Designed with aluminum or steel heating plates

- Parameter selection: Pressure, temperature, time, position, dimensions

- Low-maintenance hydraulic system with long service life

- Proprietary software and visualization

- Process data recording

- Multi-daylight design possible

- Peripheral equipment / automation available

- High vertical integration of manufacturing – Made in Germany

Press development to meet customer specifications.

Hot presses for component manufacturing from a wide range of materials.

Our hot press series

HP series

Joos quality HP presses – the classic choice

Developing high-quality hot presses demands extensive experience with hydraulic presses. Consistent pressure and heat distribution, high-quality heating and insulating elements ensure the production of high-quality components and optimize the energy footprint of the press.

BEU series

Joos quality BEU presses – entry-level model

The BEU series offers all of the innovative advantages you expect from Joos. The four models in this series have dynamic piston mounting, a high-quality hydraulic unit, the Joos A.B.S. safety system, hard anodized heating plates, and variable pressing space opening.

LAP series

Joos quality LAP presses – hot presses in a laboratory format

Innovation means development. A practical laboratory environment is essential for innovative development of new process and components using presses. Many national and international companies choose laboratory presses from Joos to handle new developments and pilot series.

In addition to our series laboratory presses, we also offer development of customer-specific hot presse as laboratory presses.

DLP series

Joos quality DLP presses – hot presses as through-feed presses

Joos stands for the high quality of the products manufactured with our through-feed presses. The DLP is a typical hot press like the ones used for wood veneers, composite materials, insulated panels, and many other materials.

Our service

Customer service on site

We place a premium on providing our customers with quick and simple support. Of course, our team is also happy to come to your location.

Telephone support

Please take advantage of our telephone service if you have any problems. Our experts are available to assist you with advice and service. If you have difficulties outside of our business hours, simply write us an e-mail.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.