Sintering presses

From powder to a solid workpiece

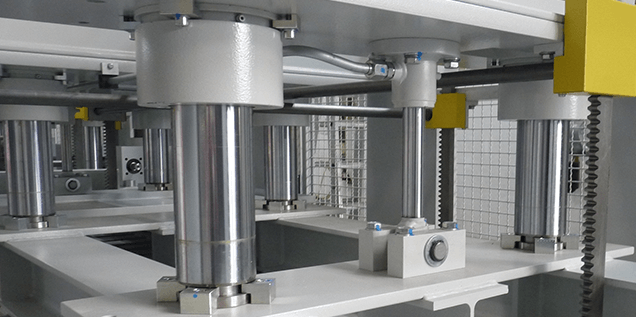

Sintering presses can be used to manufacture solid components out of powdered initial materials using pressure and temperature. In the past, the process was used primarily to manufacture ceramics. Fine-grained ceramic materials, and today metal powder or plastic granulates as well, are pressed into a solid material under high pressure and at high temperatures. The individual powdered components bond to form a solid material. The first step of production produces what is called a green body. The green body is already in the shape of the final product. However, it can be processed further. Specialized geometries or drilled holes, for example, can be added. Then the product or component is compressed and hardened below the melting temperature. Sintering presses are used to produce products out of ceramics, metals, or plastics that can be manufactured with a high level of dimensional precision and reproducibility in automated process sequences.

Joos sets new standards for sintering preses, and manufactures systems for sintering many different materials. As an experienced press manufacturer, we respond to the requirements of our industrial and research customers.

Overview of key points

- Pressing force of the machines up to 5,000 kN

- Pressing surface up to 1 x 1 m

- heating plates (aluminum or steel) up to 450 °C

- Pressure, temperature, time, position, and dimensions configurable

- Low-maintenance hydraulic sintering presses

- Proprietary software solution and data visualization

- Design as a daylight press possible

- Peripheral equipment and automation available

- Press configured according to customer specifications

Molding via pressure and temperature according to customer requirements.

Machinery from Joos stands for high dimensional precision in production.

Our service

Customer service on site

Machines can be repaired or maintained on site. Our experienced employees are available to offer service and support.

Telephone support

We are also happy to answer any questions you may have by phone. If you have problems outside of our business hours, simply send us an e-mail.

Learn more about the sintering process:

Sintering can be used to manufacture parts from initial materials that would be difficult or impossible to combine in any other manner. The product range includes simple semifinished products, as well as high-performance components for the aviation and aerospace industry. Sintered metal parts are used in gears for transmissions or engines, for example, in the automotive industry. Electric appliances can also contain sintered parts made of metal or ceramics. Sintered parts are used in technical ceramics in switch cabinets as insulating ceramic elements. The production characteristics of ceramic materials include their good thermal conductivity and high temperature resistance. In addition, they make good electrical insulators. Their applications are almost limitless.

Plastic granulates and powders can also be sintered. Polyamides or PTFE (polytetrafluorethylene) are examples of such materials. They can be sintered into semifinished products through pressing and heating, or directly into high-quality components for technical applications. Joos also delivers presses for any application in the plastics field.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.