Daylight presses

Higher productivity with multi-daylight presses

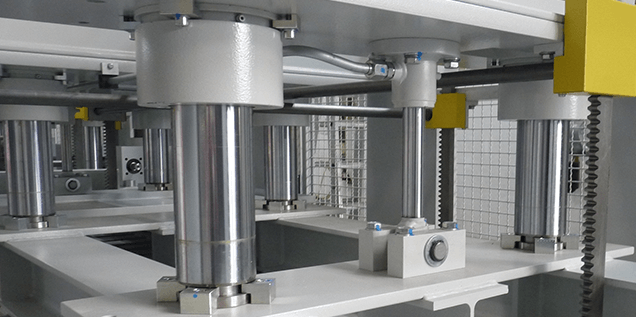

In daylight presses, multiple daylights (press levels) are installed above one another, increasing production capacity. Daylight presses are traditionally used for veneering or coating. Multiple heating plates on different levels can be used to press multiple workpieces at the same time.

Joos also delivers its series HP, BEU and LAP presses as single daylight presses, or with multiple levels. Up to 15 daylights are available. Designs are tailored to customer specifications, in terms of the number of daylights, or design as an upper piston or lower piston press. In addition to traditional applications in woodworking, multi-daylight presses are also used to press composite materials.

Overview of key points

- Pressing force up to 33,000 kN

- Press surface area up to 6 x 3 m

- Press weight up to 80 t

- Heating plates up to 450°C

- Heating and cooling plate with different heating systems

- Steel or aluminum heating plates

- Low-maintenance hydraulic system

- Long service life

- Proprietary software and visualization programs

- Peripheral equipment available

- Automation possible

- Parameter selection: Pressure, temperature, time, position

- Designed to meet customer specifications

- Development and system construction from a single source

Multiple daylights to increase production in the manufacturing process for veneer panels and coatings.

Daylight presses with innovative designs for customer-specific applications.

Our daylight press series

HP series

Joos quality HP presses – the classic choice

Joos was the first manufacturer of hydraulic veneer presses. Pioneering developments and practical solutions are implemented in our HP series. One example is dynamic piston mounting, which allows the press table to extend fully in all directions,

or the Joos A.B.S. System, which detects parts that are not picked up or set incorrectly and opens the press automatically in order to protect the heating plates.

BEU series

Joos quality BEU presses – highly adaptable

The BEU series stands out for its high level of flexibility. Customers receive a daylight press precisely designed for their application.

All of the Joos advantages you expect are also integrated into the BEU series, such as hard anodized heating plates, dynamic piston mounting, a powerful hydraulic unit, A.B.S. Safety system and variable press space opening.

Our service

Customer service on site

Good service right from the start, with ongoing consulting and advising. We offer on-site service for your press and quick repairs if necessary by a trained technician.

Telephone support

We are happy to assist you with any questions or problems. Simply call one of our technicians. You can write us an e-mail outside of business hours.

Daylight presses in use as veneer press

Coated panels or veneered chipboard are used in a wide range of different products. Furnishings, floors, doors, and even entire house facades are made of these materials. There are almost no limits to the diverse surface shapes and designs that can be produced.

A simple, single-daylight press can only apply veneer to one product at a time. In many applications, this is not an economical choice. Series production in furnishing factories requires efficient veneer presses. This is where daylight presses come into play. Veneer, base panel, and glue are inserted on multiple heating plates arranged vertically, then connected at the same time in a single pressing step. The panels are heated in this process, exercising a high level of pressure on the workpieces. This is a hot pressing process.

Hydraulic daylight presses from Joos are suitable for either trade companies or series production in factories. They are tailored to customer requirements, and can be either fed manually or fully integrated into a production line. The daylight press can even be designed initially as a single-daylight press, with the option of later expanding capacity.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.