Through-feed presses

Pressing on a running conveyor

Through-feed presses are classic presses for wood veneering. Joos is a renowned manufacturer of through-feed presses and an experienced partner to the wood processing industry. No wonder that our company headquarters has been located in the northern Black Forest for almost 150 years. Here, we are in close proximity to innovative developments for wood materials based on well-designed technology. With our DLP series of presses, we offer a modern, environmentally-friendly, and economical press series.

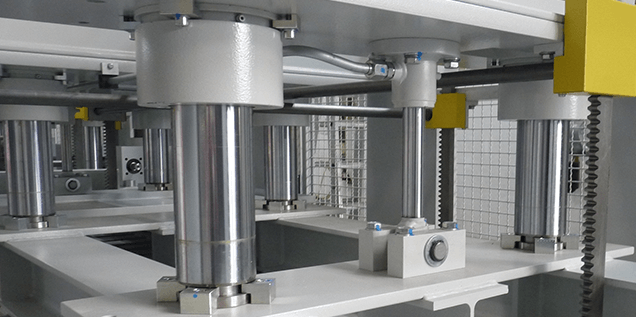

Feeding and loading are handled automatically via the infeed belt and circumferential press belt. The table used in our through-feed presses is a unique feature. Its specialized design allows the conveyor belts to be routed so that they are protected from contamination and damage. Feeding can be from the front or long side of the machine. This makes them highly flexible for integration into existing manufacturing systems. Joos manufactures the DLP both as a series product and to specific customer requirements. Using standardized components ensures simple operation and a long service life for our presses. Despite a high level of automation, and the low personnel requirements this entails, we place a premium on good ergonomics in our products to relieve strain on operators.

Our through-feed presses can do much more than press veneered woods. Other applications and materials include polyurethane, foams, insulated panels, sandwich panels, and textiles. High-tech panels used in the construction industry and products in the van and automotive sector, in particular, are becoming more and more important. Our DLPs can be used to produce roof hatches or entire side walls of an RV, for example. Our custom designed machines can be used to press panels with maximum dimensions of 18,000 mm x 3,300 mm.

Overview of key points

- Low personnel requirements

- High capacity, with low cycle times

- Full automation possible / PLC controller

- Process data recording and monitoring of pressure, time, temperature and position via proprietary software

- Easy to use operating panel

- Heating via water or thermal oil up to 250°C

- Integrated gluing

- Heating panels available in steel or aluminum

- Front or longitudinal side feeding

- Max. panel width: 1600 mm in series construction

- Custom designs up to 18,000 mm x 3,300 mm possible

Complete automation - pressing process in through-feed.

Well-designed machines from Germany with our service promise from qualified experts.

Our through-feed press series

DLP series

Joos quality DLP presses – environmentally-friendly and affordable

One unique feature of Joos through-feed presses is thermal coupling. With this feature, customers can connect the press to existing heating systems in the company to provide heating. This saves energy and investment costs.

You can choose from three different solutions:

- Use of internal heating

- Connection to customer-specific heat source

- Combination of press heating and external heat source

Our service

Customer service on site

We ensure a high level of quality through our customer-focused service. Our extensive customer service network always ensures quick contact if you need servicing or on-site repairs.

Telephone support

We provide direct telephone support for your press from an expert. We are happy to assist you by phone with advice or servicing. Outside of our business hours, simply write us an e-mail.

Hydraulic presses as through-feed presses

Fully automated hydraulic presses are an essential part of modern manufacturing. Through-feed presses can be integrated into manufacturing lines and adjusted to the speed of production. Modern control systems guarantee their reliability in series production.

Joos through-feed presses have an integrated PLC controller and an easy to operate control panel. The A.B.S. Safety system automatically detects incorrect placement or parts that are not picked up, and the press opens independently. This protects the press table, heating plates and hydraulic system from damage. The film tensioning system from Joos is designed as a quick exchange system, and can be replaced without long production downtimes. Thanks to the unique design of the press table, conveyor belts are guided around the lower heating plate, protecting them from contamination. The compact, robust design ensures a long service life and high level of reliability for our presses.

We are happy to adjust our through-feed presses to customer requirements. Learn more about the advantages of Joos through-feed presses, the system concept with standardized components, and our software and visualization programs.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.