VAK series

Vacuum presses from Joos

We have developed high-quality vacuum presses in a range of designs as a supplement to hydraulic veneer presses. The vacuum presses are suitable for many different applications, such as gluing on edges and profiles, 2D and 3D lamination, form bonding and forming thermoplastic materials. By using standardized, tested components, we guarantee simple and reliable operation and a long-lasting product.

Joos vacuum presses are available in series versions, but can also be tailored to your application. Vacuum presses can be equipped with a heated work surface, for instance. We would be happy to assist you in choosing the right vacuum pump, membrane, and heating type.

Overview

- Available as a cold press or heated using hot air, contact heat or infrared emitters

- Quick membrane exchange system allows for tool-free exchange of the membrane in just a few minutes

- Different membranes available, such as vulcanized or natural rubber or silicone

- Formed membranes for molds taller than 600 mm

- Equipped with vacuum pump with a rate of 40 m³/h

For processing wood and thermoplastic materials.

Vacuum presses for industrial applications.

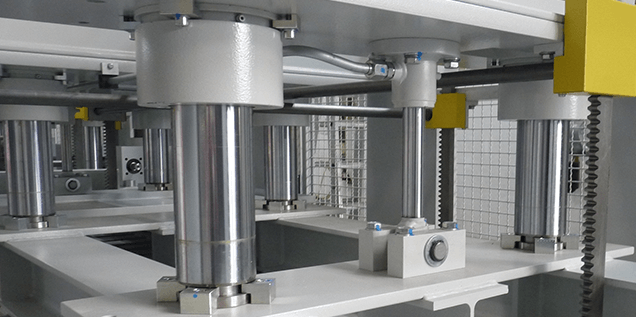

Welded base frame

The torsionally stiff base frame of the press is welded out of steel profiles, and is suitable for holding heavy molded parts.

1 of 7Work surface

The water-tight, resistant work surface has cross-milled grooves to better distribute the vacuum pressure. The work surface is exchangeable.

2 of 7Switch cabinet

The operating elements for the press are integrated into the switch cabinet and easy to understand.

3 of 7Vacuum pump and vacuum tank

The vacuum pump and vacuum tank are permanently installed in the base frame of the press.

4 of 7Welded aluminum profile frame

The welded aluminum profile frame increases the stability of the cover and tightness of the vacuum system.

5 of 7Clamped membrane

The membrane, which is clamped in the double frame, can be exchanged quickly and easily without tools in just a few minutes.

6 of 7Thermal hood

The adjustable temperature up to 90°C accelerates curing time for pressed parts. Depending on table size, the connection power is 2.0 – 4.0 kW.

7 of 7VAK series models

VAK 1515

-

Work surface 1300x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 700x700 mm

-

Pump size 16 m³/h

-

Weight 350 kg

VAK 2015

-

Work surface 1800x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 1200x800 mm

-

Pump size 16 m³/h

-

Weight 450 kg

VAK 2515

-

Work surface 2300x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 1700x800 mm

-

Pump size 16 m³/h

-

Weight 500 kg

VAK 3015

-

Work surface 2800x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 2200x800 mm

-

Pump size 40 m³/h

-

Weight 540 kg

VAK 3515

-

Work surface 3300x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 2700x800 mm

-

Pump size 40 m³/h

-

Weight 580 kg

VAK 4015

-

Work surface 3800x1300 mm

-

Mold height 600 mm

-

Recommended mold dimensions 3200x800 mm

-

Pump size 40 m³/h

-

Weight 630 kg

Special sizes upon request

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.