Short-cycle presses

Coating in short cycle

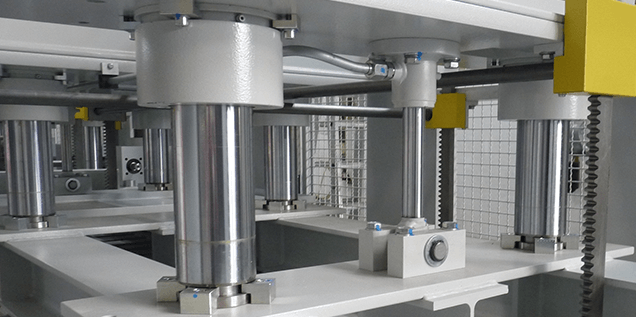

A short-cycle press is a hydraulic press optimized for the shortest possible cycle times. Short-cycle presses are used, for instance, as veneer presses in furniture production. The short cycle times are achieved by timing and speed optimization of the heating capacity, opening speeds, closing speeds, and tempo of press feeding and unloading. Short-cycle presses can be integrated into existing systems and production lines. They deliver a high level of reliability and economic efficiency in such applications. In furniture manufacturing, short-cycle presses are used to feed panels in the production cycle through a fully automated process. This allows the system to work essentially as a through-feed press.

Joos is a traditional company from the Black Forest that has been building presses for over 80 years. As a market leader in veneer presses, we are very familiar with the high demands placed on modern short-cycle presses.

Overview of key points

- Short cycle times

- Pressing force of the short-cycle press up to 33,000 kN

- Press surface area up to 18 x 3 m

- Press weight of short-cycle presses up to 80 t

- Temperature of heating and cooling plates up to 450°C

- Heated with water or thermal oil

- Heating plate materials: Aluminum, steel

- Parameter selection: Pressure, temperature, time, position, dimensions

- Customized proprietary software and visualization solutions

- With press peripheral equipment / automation solutions

- High vertical integration of manufacturing and quality

Integration into ongoing production operations.

Short-cycle presses designed to meet customer requirements.

Our service

Customer service on site

Thanks to our excellent customer service network, we can be on site quickly to provide service for your press - with the level of qulaity you expect from Joos.

Telephone support

Please contact our telephone service team if you have questions or problems. You are welcome to write us an e-mail outside of our business hours.

Information on short-cycle coating

Many of the products coated using our systems, in particular furniture, flooring, ceiling panels, etc. are manufactured in short cycles. This includes a diverse range of products: Furniture panels made of solid wood, MDF panels, chipboard or plywood panels are used as base panels. Our presses coat these with veneers, melamine-impregnated papers, and other textured or decorative surfaces.

To work at the speed of production, the presses need to combine quick heating times with short opening and closing times. Panels are usually fed using a belt. The pressing process follows feeding. Finally, the pressed parts leave the press on the other side, on another conveyor belt which takes them to the next step of production. We would be happy to provide the peripheral equipment and automation software necessary for this process.

However, the presses can be used for much more than applying veneers. Presses from Joos are used to press a wide range of new products, like textiles, foams, insulation materials and sandwich panels. We build our presses for customers from industrial sectors like wood processing, van, automotive, aviation, and aerospace technology and the recycling industry.

Joos manufactures presses according to customer specifications, tailored to any application. We fulfill high standards, and deliver durable and economical machines.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.