Vacuum presses

Molds under pressure – vacuum presses

We developed our vacuum presses for shaped gluing of wood and forming thermoplastic materials. Pressure distribution in the press is particularly even, since the air pressure is applied to the entire workpiece via the membrane.

Workpieces are positioned in the press under a membrane. A vacuum pump is then used to suction the air out of the intermediate space. The membrane surrounds the workpiece and atmospheric pressure (approx. 1 bar) acts on the component. Vacuum presses are used anywhere air inclusions need to be avoided in veneer application or coating. Vacuum presses are also used to produce circuit boards or manufacture photovoltaic modules.

Joos offers two models. The first is the Heavy Line, with a welded, torsionally stiff base frame for trade customers – for low quantities and smaller components. The tight vacuum and stability ensure outstanding customer satisfaction.

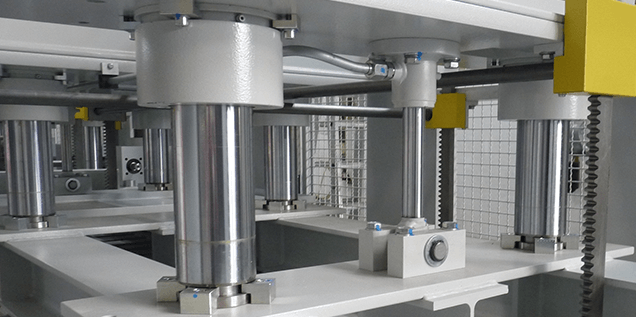

The second option is the Industrial Line, the ideal vacuum press for industrial production of large components. It can be integrated into existing production lines, and has a 4 column design that provides multiple advantages, such as open access for large and complex components. This production machine can be integrated optimally into production with corresponding feeding aids.

Overview of key points

- Stable table design (load capacity up to 500 kg)

- Exchangeable plate

- Water-tight, resistant work surface

- Cross milled grooves in the work surface for optimal vacuum distribution

- Simple membrane exchange

- Vacuum level electronically adjustable

- Oil-lubricated vacuum pump installed securely

- Thermal hood over hot air (standard up to 90°C)

- Special design of thermal hood up to 140°C

- Special design with heated work surface

- Standardized components

Molds for the application can be produced inexpensively.

Membrane materials: Rubber or silicone.

Our vacuum press series

VAK series

Joos quality VAK – HEAVY LINE, INDUSTRIAL LINE presses

Our Heavy Line vacuum presses were developed as series production machines, and can also be delivered in customer-specific versions. The highly torsionally stiff base frame allows heavy molded parts to be placed inside the press.

Joos Industrial Line presses are designed for industrial applications, and are used as four-column presses for large and complex components as well as series production. Setup times in production are reduced thanks to the unique membrane quick exchange system.

Our service

Customer service on site

Our extensive network of dealers and customer service agents allows us to carry out service, maintenance and repair of your vacuum presses directly on site.

Telephone support

If you have questions or problems regarding your vacuum press, simply give us a call or write us an e-mail. We would be happy to support you.

Vacuum press example applications

Vacuum presses can be used in a wide range of applications in furniture production, for shaped gluing, veneer application, coating, sheathing, and laminating, or for molding thermoplastic materials such as acrylic glass. In shaped gluing, parts are molded into a certain shape using a template (negative mold). Molded parts can be made of different materials and multiple layers (veneers, honeycomb construction, etc.).

Coating or laminating is a process by which flat or shaped components are covered with a film or veneer. 2D or 3D lamination is used for kitchen cabinet fronts and profiles. In solid gluing, edges or profiles are glued onto components.

In addition, vacuum presses can be used to mold thermoplastic materials. Designer parts, vanities, and other products are made of materials like acrylic glass or Corian.

SET UP A CONSULTATION APPOINTMENT

We would be glad to offer you a thorough and non-binding consultation on our presses. Make your appointment now.

REQUEST AN OFFER

We would be glad to prepare a non-binding offer for you for one of our high-quality, high-performing presses.